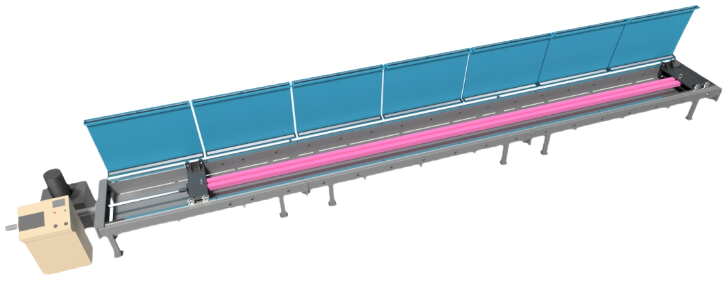

Horizontal Tensile Test Machine

AJT Horizontal Tensile Test Machines are Models 174E (manually controlled) / 177PC (PC controlled) / 177PLC (PLC controlled).

These are available in length, width, height and capacity to suit your company’s testing requirements.

Features

- Base design to suit a wide range of applications

- Customised to your specific testing requirements

- Any capacity

- Made to any required length

- Displacement sensor available

- Modular design, extendable at any time

- Fitted with our own strain-gauge load cell

- Grip attachments available

- Safety orientated design including manual protective guards, automated protective guards and minimum load on sample features

- Optional data logging or PC control

- Can integrate with your existing data network

PERFECT FOR TESTING

Steel Wire Rope

Fibre Rope

Shackles

Slings

Ratchet Straps

Hoses

Fibre Optic Cables

Conductor Cables

Chains

Belts

SUPPORT

AJT provides worldwide on-site and remote support for sales, installation, training, service, and calibration.

Supplied with the following as standard

Calibration Certificate to 7500-1:2018 +/-1%

Operational Manual in English

Declaration of Conformity or Incorporation

12 Month Warranty

OPTIONAL EXTRAS

Certificate of Origin

Operational Manual in any language

User training with certification

Tailored calibration and service contract

Extended Warranty

AJT’s Horizontal Tensile Test Machine is a highly versatile piece of equipment that can adapt to various testing requirements, meaning it can be used across many industries and for a wide range of materials. It offers a flexible base to perform all types of tests within a single machine, making it a cost-effective option.

The modular beds can be made to any length, allowing for customisation based on the specific needs of the test. This design also means they can be extended to increase the test length at a later date if required. Plus, it makes shipping and handling the machine much easier, quicker and more affordable.

Altering the required sample length on a test by test basis is also very quick and easy to do. The static end of the machine is adjustable by using a very simple, ergonomic system. The carriage is on rollers and secured with high tensile steel pins, which can be removed to allow the operator to easily move the carriage to a desired location point along the machine frame, before the pins are reinserted.

The machine includes essential safety features, such as manual or automated protective guards, emergency stops, and minimum load on sample, with all stresses contained within the structure of the machine. These features prioritise user safety during testing operations.

AJT have produced this machine (each one bespoke) for customers all over the world, with capacities ranging from 5 Tonnes to 3000 Tonnes thus far. We have our own in-house design team with CAD facilities so we can work together to bring your vision to fruition.

The machine can be equipped with data acquisition software, or a full PC control system, and can also be integrated with your existing data network. This facilitates real-time monitoring and data analysis, enhancing the efficiency and accuracy of testing processes. Alternatively, we can produce basic, manually controlled machines for stricter budgets.