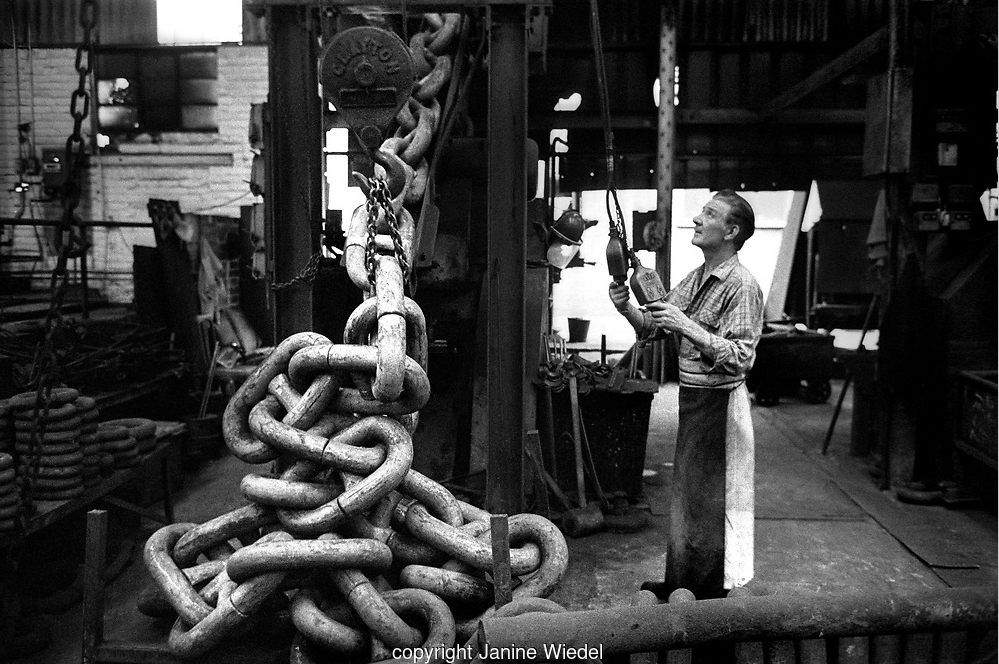

The Black Country, located in the heart of England, is renowned for its rich industrial heritage, particularly in chain making, which became popular due to the considerable resources of coal and iron.

The region played a pivotal role in the Industrial Revolution, shaping not only the landscape and economy of the local area but also contributing significantly to the advancement of industrial processes worldwide. With the vast number of factories emerging, air pollution began to take over the region, making it “black by day and red by night”. As a result, the term “Black Country” was born.

The importance of testing a length of chain to ensure its suitability and strength for a particular job was realised early in the history of the trade. In 1812, Samuel Brown had a testing machine constructed at his chainworks in London. This enabled him to find out where defects in the material, construction and workmanship lay, and thereby gradually to improve the quality of his cables. He also used this machine to test the mechanical properties of the iron he was supplied with.

It was not until 1846 that the Rules of Lloyds Shipping Register made it their surveyors’ duty to see that ships cables had been tested and that the strain applied had been stamped on each length. Even so, the quality and therefore the safety of these early chain cables varied enormously, and so did the tests that were applied to them.

The Act stated, “from and after the first day of July 1865, it shall not be lawful for any maker or dealer in chain cables or anchors to sell or contract to sell the use of any vessel any chain cable whatever or any anchor exceeding in weight 168 pounds unless such chain cable or anchor shall have been previously tested and duly stamped in accordance with the provisions of this Act.” The penalty for contravening this was a fine of up to £50. In today’s money, that’s around £8000! In later years, several amendments were made but the basic requirements of tensile and breaking strain tests remained unchanged. Cable that withstood the strain was stamped as “PROVED”.

In 1951, AJT Equipment was established with the purpose of manufacturing test machines for the Black Country chain makers. Today, through continued advancement and technical requirements, AJT Equipment build machines for tension, compression, static, dynamic, flex, fatigue, drop, impact, crush and bend testing in many industries, including Marine, Oil and Gas, Rope Manufacturing, Toilet Manufacturing, Lifting Gear, Military, Rigging, Transport, Telecommunications, Renewable Energy, Offshore, Aerospace, Staging, Aviation, Automotive, Chains and many more!